Pressure Transducers

Introduction to Pressure Transducers and Transmitters

A

pressure transducer, often called a

pressure transmitter, is a transducer that converts pressure into an analog electrical signal. Although there are various types of pressure transducers, one of the most common is the strain-gage base transducer.

The conversion of pressure into an electrical signal is achieved by the physical deformation of strain gages which are bonded into the diaphragm of the pressure transducer and wired into a wheatstone bridge configuration. Pressure applied to the pressure transducer produces a deflection of the diaphragm which introduces strain to the gages. The strain will produce an electrical resistance change proportional to the pressure.

OMEGA Engineering offers a wide range of

pressure transducers in Australia.

Learn more about pressure transducers

The Electrical Output of Pressure Transducers

Pressure transducers are generally available with three types of electrical output; millivolt, amplified voltage and 4-20mA. Below is a summary of the outputs and when they are best used.

Millivolt Output Pressure Transducers

Transducers with millivolt output are normally the most economical pressure transducers. The output of the millivolt transducer is nominally around 30mV. The actual output is directly proportional to the pressure transducer input power or excitation. If the excitation fluctuates, the output will change also. Because of this dependence on the excitation level, regulated power supplies are suggested for use with millivolt transducers. Because the output signal is so low, the transducer should not be located in an electrically noisy environment. The distances between the transducer and the readout instrument should also be kept relatively short.

Voltage Output Pressure Transducers

Voltage output transducers include integral signal conditioning which provide a much higher output than a millivolt transducer. The output is normally 0-5Vdc or 0-10Vdc. Although model specific, the output of the transducer is not normally a direct function of excitation. This means unregulated power supplies are often sufficient as long as they fall within a specified power range. Because they have a higher level output these transducers are not as susceptible to electrical noise as millivolt transducers and can therefore be used in much more industrial environments.

4-20 mA Output Pressure Transducers

These types of transducers are also known as pressure transmitters. Since a 4-20mA signal is least affected by electrical noise and resistance in the signal wires, these transducers are best used when the signal must be transmitted long distances. It is not uncommon to use these transducers in applications where the lead wire must be 1000 feet or more.

Choosing Pressure Transducer

Still wondering how to decide what type of pressure transducer or pressure transmitter you need? To learn more about the criteria you should think about when making your decision, below will help you pick out the right device for your application.

Choose the right pressure transducer for your application

PC Board Mountable Pressure Transducers

PC Board Mountable Pressure Transducers

PC board mountable pressure transducers are generally compact economical pressure transducers designed to mount on an electrical PC board and be integrated into other products.

General Purpose Transducers

General Purpose Transducers

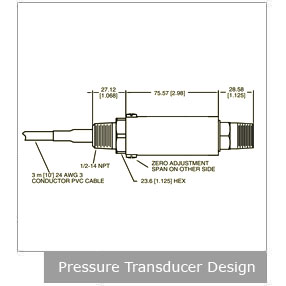

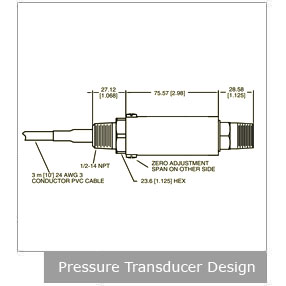

General purpose pressure transducers are the most common since they are designed to fit the broadest set of applications.

Heavy Duty/Industrial Pressure Transducers

Heavy Duty/Industrial Pressure Transducers

Heavy Duty/Industrial Pressure transducers feature a much more rugged enclosure than other transducers. They are designed to accommodate heavy industrial environments. They also often feature a scalable 4-20mA output that provides much greater immunity to electrical noise which is not uncommon in industrial environments.

High Stability/High Accuracy Pressure Transducers

High Stability/High Accuracy Pressure Transducers

Most pressure transducers feature an accuracy of 0.25% of full scale or higher. High stability and high accuracy pressure transducers can offer errors as low as 0.05% of full scale, depending on model. Although more expensive than general purpose transducers, they may be the only option if high precision is required.

Flush Diaphragm Pressure Transducers

Flush Diaphragm Pressure Transducers

With flush diaphragm pressure transducers, the diaphragm is flush to the process. This eliminates a cavity above the diaphragm that could collect fluid matter from the process. In certain applications, this may be very undesirable. Those applications include monitoring the pressure of foods or liquids that have very high viscosity.

Special Purpose Transducers

Special Purpose Transducers

OMEGA offers a variety of pressure transducers with special features. These include pressure transducers designed for pressure measurement in very high or low temperatures, submersible pressure transducers, barometric pressure transducers and pressure transducers with digital communications output or wireless outputs.

Frequently Asked Questions

What is the most common indicator that a transducer has been overpressured?

The most common indcation that a transducer has been overpressured is a shift in the zero reading usually in an increasing direction. It may read 5-6 ma or even higher. It can even saturate at a maximum value which is typically around 24 ma.

Shop for Pressure Transducers in Australia

The OMEGA Engineering Singapore office handles all inquiries and orders for Australia. We have Application Engineers and Sale Support Staff ready to assist you with your technical questions, quotations and orders. A one-stop source for process measurement and control, OMEGA provides support through web chat, e-mail and telephone. View our

contact page to call or email us.

Pressure Transducer | Related Products

↓ View this page in another language or region ↓

PC Board Mountable Pressure Transducers

PC Board Mountable Pressure Transducers

General Purpose Transducers

General Purpose Transducers

Heavy Duty/Industrial Pressure Transducers

Heavy Duty/Industrial Pressure Transducers

High Stability/High Accuracy Pressure Transducers

High Stability/High Accuracy Pressure Transducers

Flush Diaphragm Pressure Transducers

Flush Diaphragm Pressure Transducers

Special Purpose Transducers

Special Purpose Transducers

Transdutores de Pressão

Transdutores de Pressão

Transmetteurs de Pression

Transmetteurs de Pression

Transductores de Presión

Transductores de Presión

Transductores de Presión

Transductores de Presión

Pressure Transducers

Pressure Transducers

Tryktransducere

Tryktransducere

Transducteurs de Pression

Transducteurs de Pression

Druckaufnehmern

Druckaufnehmern

Trasduttori di Pressione

Trasduttori di Pressione

Pressure Transducer

Pressure Transducer

Transductor de Presión

Transductor de Presión

Pressure Transducer

Pressure Transducer

Pressure Transducers

Pressure Transducers

Pressure Transducer

Pressure Transducer

圧力トランスデューサー

圧力トランスデューサー

압력센서

압력센서

Pressure Transducers

Pressure Transducers

Pressure Transducers

Pressure Transducers

Pressure Transducers

Pressure Transducers

Pressure Transducers

Pressure Transducers

Pressure Transducers

Pressure Transducers