A thermal imager is a non-contact temperature measurement device. Thermal Imagers detect the infrared energy emitted, transmitted or reflected by all materials -- at temperatures above absolute zero, (0°Kelvin)-- and converts the energy factor into a temperature reading or thermogram. A thermogram is the thermal image displayed by the camera of the object which is emitting, transmitting or reflecting the infrared energy.

OMEGA Engineering offers a wide range of

thermal imagers in Australia.

Why Thermal Imaging?

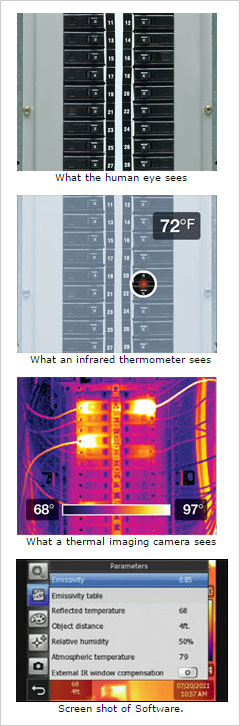

While spot infrared thermometers present only a single temperature at a single spot, these Thermal Imaging Cameras give you the whole picture, some up to 19,600 spots! Thermal imaging is the most effective method for finding problems or potential problems in a variety of applications across many fields.

Why should I use a thermal imager to measure temperature in my application?

Thermal imagers allow users to measure temperature in applications where conventional sensors cannot be employed. Specifically, in cases dealing with moving objects ( i.e., rollers, moving machinery, or a conveyor belt), or where non-contact measurements are required because of contamination or hazardous reasons (such as high voltage), where distances are too great, or where the temperatures to be measured are too high for thermocouples or other contact sensors. The thermal imagers provide an image which shows the temperature difference of the object being measured. Hot spots can be seen immediately versus traditional infrared guns which average the area being measured.

Why is resolution important?

A higher resolution camera means you will find smaller problems at greater distances. You can find significant problems that could be missed with a lower resolution camera. For example a pc board can have a component which is overheating. A thermal imager will instantly find the hot spot.

What should I consider about my application when selecting a thermal imager?

The critical considerations for any thermal imager include field of view (target size and distance), type of surface being measured (emissivity considerations), spectral response (for atmospheric effects or transmission through surfaces), temperature range and mounting (handheld portable or fixed mount). Other considerations include response time, environment, mounting limitations, viewing port or window applications, and desired signal processing.

What is meant by Field of View, and why is it important?

The field of view is the angle of vision at which the instrument operates, and is determined by the optics of the unit. To obtain an accurate temperature reading, the target being measured should completely fill the field of view of the instrument.

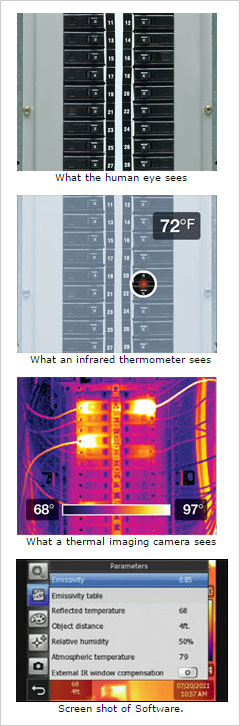

What is emissivity, and how is it related to infrared temperature measurements?

Emissivity is defined as the ratio of the energy radiated by an object at a given temperature to the energy emitted by a perfect radiator, or blackbody, at the same temperature. The emissivity of a blackbody is 1.0. All values of emissivity fall between 0.0 and 1.0. Most infrared thermometers have the ability to compensate for different emissivity values, for different materials. In general, the higher the emissivity of an object, the easier it is to obtain an accurate temperature measurement using infrared. Objects with very low emissivities (below 0.2) can be difficult applications. Some polished, shiny metallic surfaces, such as aluminum, are so reflective in the infrared that accurate temperature measurements are not always possible.

Five Ways to Determine Emissivity

There are five ways to determine the emissivity of the material, to ensure accurate temperature measurements:

- Heat a sample of the material to a known temperature, using a precise sensor, and measure the temperature using the IR instrument. Then adjust the emissivity value to force the indicator to display the correct temperature.

- For relatively low temperatures (up to 500°F), a piece of masking tape, with an emissivity of 0.95, can be measured. Then adjust the emissivity value to force the indicator to display the correct temperature of the material.

- For high temperature measurements, a hole (depth of which is at least 6 times the diameter) can be drilled into the object. This hole acts as a blackbody with emissivity of 1.0. Measure the temperature in the hole, then adjust the emissivity to force the indicator to display the correct temperature of the material.

- If the material, or a portion of it, can be coated, a dull black paint will have an emissivity of approximately 1.0. Measure the temperature of the paint, then adjust the emissivity to force the indicator to display the correct temperature.

- Standardized emissivity values for most materials are available. These can be entered into the instrument to estimate the material's emissivity value.

Which Thermal Imager is right for my application?

Buy an infrared camera with the highest detector resolution/image quality that your budget allows.Most infrared cameras have fewer pixels than visible-light cameras, so pay close attention to detector resolution. Higher resolution infrared cameras can measure smaller targets from farther away and create sharper thermal images, both of which add up to more precise and reliable measurements.

Also be aware of the difference between detector and display resolution. Some manufacturers will boast about a high resolution LCD and hide their low resolution detector when it's the detector resolution that matters most.

Need to present findings to others? Find a system with a built-in visible-light camera outfitted with an illuminator lamp and a laser pointer.

Digital photos that correspond to your IR images will help you further document a problem and communicate its precise location to decision-makers. Laser markers show up clearly on visible light pictures.

Select a camera that delivers accurate and repeatable results.

Infrared cameras don't just let you see differences in heat, they let you measure those differences. For best results, look for a thermal imager that meets or exceeds ±2% (or 3.6°F) accuracy. Your thermal imager should include in-camera tools for entering both "emissivity" and "reflected temperature" values. An infrared camera that gives you an easy way to input and adjust both of those parameters will produce the accurate temperature measurements you need in the field to make the best call.

Look for an IR camera that stores and outputs standard file formats.

Many infrared cameras store images in a proprietary format that can only be read and analyzed with specialized software. Standard JPEG with full temperature analysis embedded allows you to e-mail IR images to your customers or colleagues without losing that vital information. Also, look for infrared cameras that allow you to stream MPEG 4 video via USB to computers and monitors.

Consider Bluetooth and Wi-Fi

New test and measurement tools wirelessly transmit vital diagnostic data such as humidity, amperage, voltage, and resistance directly to the camera. The data is annotated automatically to the thermal image and embedded in the radiometric JPEG to support IR findings. Using WiFi and mobile device apps, the ability to send thermal images and IR inspection reports from one part of a facility to another or by email from the field is huge, especially when time is of the essence.

Ergonomic Features

A lighter thermal camera will decrease strain on your shoulder and back during long inspections. Some models have lens systems that tilt along a 120 degree axis allowing users to keep the viewing screen comfortably in front of them. An extra button or two can actually make the camera easier to use as opposed to using one button to step through a maze of menu options. Buttons should be intuitively positioned and comfortable to use. Some cameras offer integrated touch screens.

Picture-in-Picture (P-i-P) and/or image fusion

Allows you to combine thermal and visible-light images for generating reports that are easier to understand.

Reporting Software

Can you create instant reports right from the camera, or on your mobile device with Wi-Fi enabled cameras? Can it perform a wide range of tasks from simple spot measurements to custom radiometric calibrations, or create specialized data analysis using third party software like MatLab™ or Excel?

Temperature Range

A camera's temperature range and sensitivity are important considerations, too. The range tells you what the minimum and maximum temperatures are that the camera can measure (-4°F to 2,192°F is a typical example).

Protect your Investment

Look for cameras with a comprehensive, extended warranty program to protect your investment for the long haul.

Technical Support and Training

The quality of customer service and the depth of technical support available should be integral to your decision on which infrared camera to purchase.

See

"12 Things to Consider Before Buying an Infrared Camera, A Guide for Investing in Infrared" by FLIR to learn about this in more depth.

Portable Thermal Imagers

Portable Thermal Imagers

Fixed Mount Thermal Imagers

Fixed Mount Thermal Imagers